ball nose end mill uses

Ad Large Selection of End Mills From General Purpose Modular High-Performance End Mills. Stub Length Ball End Mill.

Ball Nose Milling Strategy Guide In The Loupe

And they are not so great on milder material like aluminum either.

. The smaller diameters can be used for engraving. Ball nose mills have a radius at the bottom which makes for a nicer surface finish in your workpiece meaning less work for you as the piece wont need to be finished any further. Ball Nose End Mills.

Bull Nose End Mills Corner Radius Bull end mills are simply corner radius end mill cutters. Explore more on it. Harder than carbide end mills theyre better for making small precise cuts.

High-Precision Cubic Boron Nitride Ball EndMills for Tool Steel and Hardened Steel. These excel at high-detail contours like relief artwork or mold and die making but have what is known as scalloping Since the tip of the end mill is round having a perfectly flat surface is a challenging feat and will take many more passes than a simple fishtail to smooth. For multi-material with hardness 48 HRc.

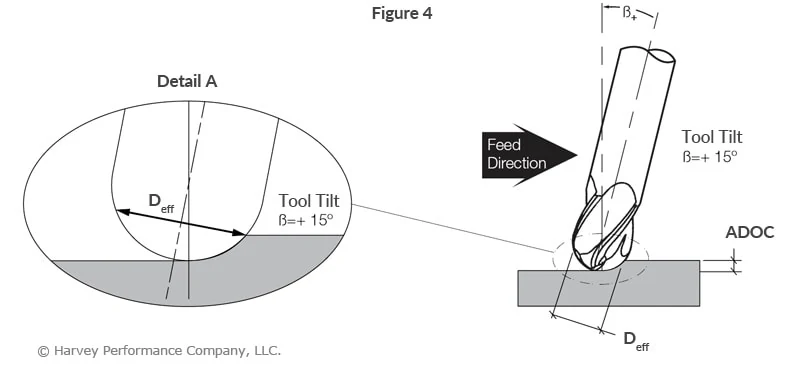

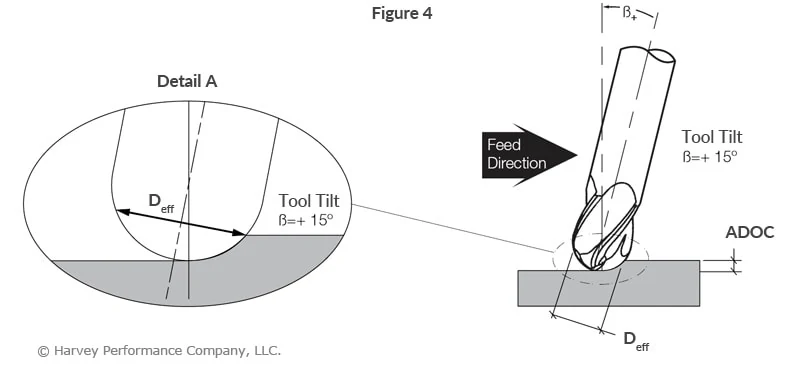

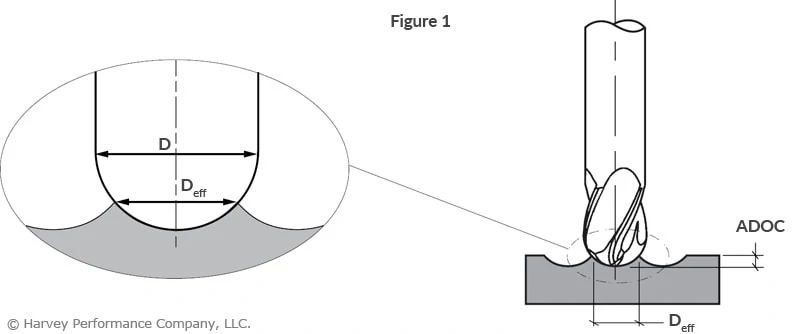

To properly employ a ball nose end mill with no tilt angle and gain the optimal tool life and part finish follow the 2-step process below see Figure 1. Make finishing cuts in tool steel and hardened steel with these cubic boron nitride CBN end mills. This enables a cnc machine to machine complex flowing shapes to reproduce decorative attractive projects.

Corner radius end mill cutters have a stronger milling edge than square end mills so feed rates may be increased and yield longer tool life and greater productivity. For multi-material with hardness 48 HRc. In general ball nose and corner rounding cutters require more cutting pressure which results in a poorer finish on steel.

Slopes found in sculptured forms are from 0 to 90 and the fillet radius can in some applications be very small. There are also bull nose end mills these have radiused corners that are smaller than the radius of the cutter. A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds.

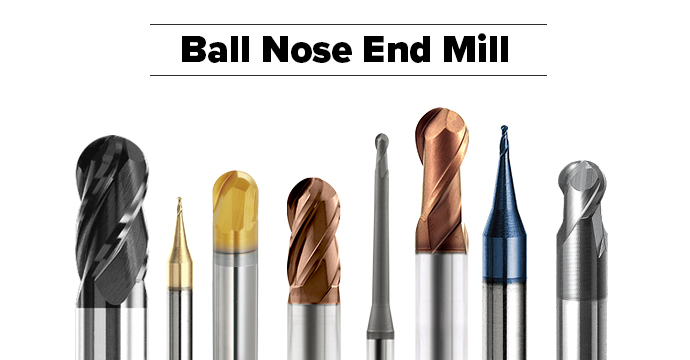

Ball nose end mill is a kind of tool which is assembled on the milling machine with the cutter similar to the ball head and is used for milling various curved surfaces and arc grooves. Ball nose spiral end mills are used for smooth contouring and fine detail passes with a CNC router and often for complex shapes like 3D carvings. Also called Ball Nose End Mills they are used extensively in manufacturing tools dies and machining complex three dimensional contours with a smooth finish.

Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing. These radius end mills are single ended tools used for making corner radii at the bottom of a milled shoulder. They are used for contour milling shallow slotting pocketing and contouring applications.

The ball nose end mill has the best effect on the machining curved surface but the chip discharge performance is poor because of the small chip holding groove at the tip. CoroMill Plura Solid Carbide Ball Nose End Mill for Profiling. Ad Our Philosophy Is To Make Lives Simpler By Solving Problems.

Not that they cant do a good a good job under the right circumstances but in general ball nose and corner rounding end mills are only for cosmetic features. They can be used used for milling a large corner radius grooving with a full radius and contour or profile milling. Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing.

What is a ball end mill used for. Ball-Nose End Mills. Ball End Mills are very durable and come with an array of surface coatings tailored for milling a wide range of materials from plastics to titanium and steel alloys.

Four or more fluted ball nose end mills have less chip evacuation due to their design but with multiple cutting edges they can produce very smooth finish by running lighter chip loads without sacrificing a high rate of production. Ball Nose End Mill HRC 50 55 65 Tungsten carbide Cutting Tools End Milling The products are pretty goodThe precision and working life is higher. Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing.

View Kennametal End Mill Catalog For Application Corner Configuration Diameter More. Standard Length Ball End Mill. A ball end mill is constructed of a round cutting edge.

Small diameter ball nose end mills are used for projects with intricate detail while larger bits are used for smoother projects with more. There are a few ball end mill uses the big one being the ability to produce free form curves. Read customer reviews find best sellers.

Ball-nose end mills have a dome-shaped tip. Find your tool and buy. Ball nose end mills are ideal for machining 3-dimensional contour shapes typically found in the mold and die industry the manufacturing of turbine blades and fulfilling general part radius requirements.

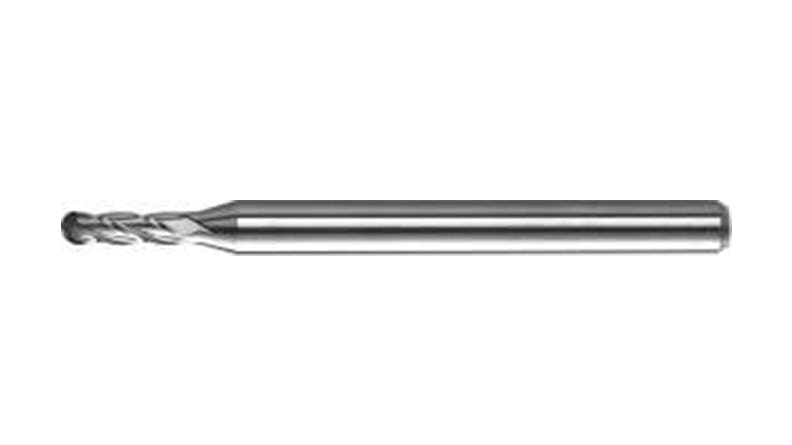

The rounded ends produce smooth curves that would be impossible to achieve with flat end bits. A ball end mill is constructed of a round. The design of a two flute ball end mill allows for plenty of chip evacuation making them most effective in contouring deep pockets in molds and dies.

They are available in a wide variety of standard sizes and lengths. Ball-end milling must remove a 03 mm allowance in the finishing pass using ball-end mills with diameters less than 20 mm to reproduce the free-form small features. Ad Browse discover thousands of brands.

1 8 125 Ball Nose End Mill Digital Wood Carver

Cnc End Mill Selection Guide For The Beginners Speed Tiger Cutting Tool

Yonico 2 Flute Ball Nose Spiral End Mill 1 8 In Dia 1 4 In Shank Solid Carbide Cnc Router Bit 34210 Sc

What S The Difference Between Flat Ball Angle Radius End Mill

Basic End Mills Technical Information Msc Industrial Supply Co

Micro Ball Nose End Mill Main Geometric Features Download Scientific Diagram

The Machining Costs You Should Consider When Designing With Chamfers And Fillets

End Mills The Essential Beginners Guide

Ball Nose Milling Strategy Guide In The Loupe

End Mills The Essential Beginners Guide

Ball Nose End Mill Cutter Puri Tools Steel Trader Mumbai India

Skip To Content Robbjack Corporation Menu Solutions Spotlight Making The Switch To Aluminum For Lightweight High Performing Automotive Applications Only Robbjack S A1 303 Met This Machining Requirement Where Over 20 Other Toolmakers Failed See

Cnc End Mill Selection Guide For The Beginners Speed Tiger Cutting Tool

Ball Nose End Mill Cutter Puri Tools Steel Trader Mumbai India

Ball Nose End Mill Cutter Puri Tools Steel Trader Mumbai India

Ball Nose Milling Strategy Guide In The Loupe

Basic End Mills Technical Information Msc Industrial Supply Co